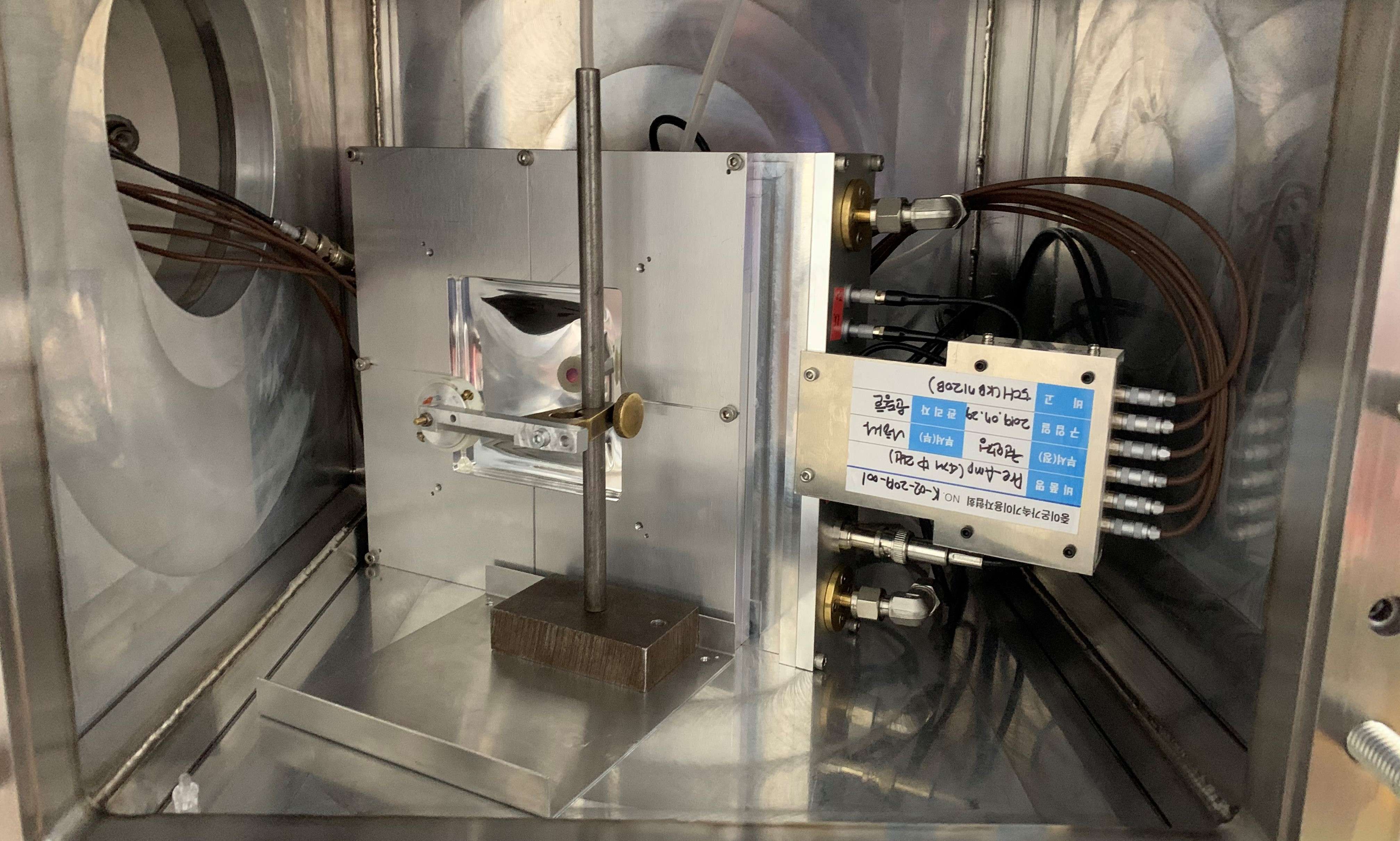

On the ACCULINNA-2 separator is beeing implemented a system of PPAC (Parallel Plate Avalanche Counter) position-sensitive detectors. Functions of the detectors is to measure a beam's profile and determine its focal point. For the proper operation of the detectors, it is necessary to guarantee the stability of a flow, pressure and power supply of the devices. Changing any of these crucial parameters makes the collected data unreliable. For this purpose, utmost attention is paid to creating a system providing the stability of the detectors operation. During the internship, a control system will be developed (for the already built station) to control the detectors parameters. The PID regulator will also be optimized to make the system resistant to an external interference. Finally, the detectors will be calibrated and prepared to a future application.

Tasks

Familiarization with the experimental station for PPAC gas detectors. The software for operating with PPAC detectors will be developed. The created software will control the gas flow, pressure sensors and suplied voltage, and the collected data will be visualised. The PID controller's calibration will be performed. Finally, the working point will be found and the analise of the physical data (gets with usage an alfa source) will be done.

Preliminary schedule by topics/tasks

Familiarization with the LabVIEW environment (1st week)

Working with RS-232, RS-422, RS-485 serial communication protocols and creating communication scripts for selected devices (a flow controller, a power suplier, a pressure logger) (2st week)

Development of a software for the control of the station for working with a PPAC detector (3rd week)

Data visualization and analysis with Matlab software (4st week)

PID controller calibration (5st week)

Required skills

English level B2, Basic knowledge of programming (LabVIEW and Matlab), Basic knowledge of signal processing, Basic knowledge of an automation (PID regulation) and a metrology methods

Acquired skills and experience

Knowledge about the creating software for continuous control and monitoring of physical experiments

Knowledge of serial communication protocols

Tuning PID controller settings

Determining the working point of PPAC detector

Recommended literature

For later consultation with the student